Will Hanna

Member

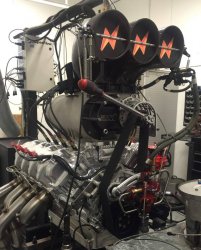

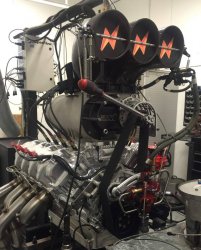

InsideProMod.com got a chance to talk with Jamie Noonan of Noonan Ultimate Race Engineering about their new 4.900 Bore space hemi engine they debuted at the PRI Show. We chose this as our 'first' tech article, because we believe that the 4.9 hemi will sure to be a game changer in legal and outlaw Pro Mod.

InsideProMod (IPM): Tell us the basics of this new motor. What are the major differences in the 4.9 Hemi and the 4.8 Hemi (Fathead style that most run), and why did you go in that direction?

Jamie Noonan (JN): "Obviously the bore center was a big factor. We went from 4.8 to 4.9 bore centers. So we can actually take up to 4.600 bore now where we were limited to 4.500 bore before. Which allows us for the PDRA Pro Mod cars to run a much bigger intake and exhaust valve than we could with the 4.500 bore. Not only did we go bigger with the valves, we stood the valve angles up three degrees so it flattens the chamber out, and raised the port up half an inch on intake and exhaust.

Jamie Noonan (JN): "Obviously the bore center was a big factor. We went from 4.8 to 4.9 bore centers. So we can actually take up to 4.600 bore now where we were limited to 4.500 bore before. Which allows us for the PDRA Pro Mod cars to run a much bigger intake and exhaust valve than we could with the 4.500 bore. Not only did we go bigger with the valves, we stood the valve angles up three degrees so it flattens the chamber out, and raised the port up half an inch on intake and exhaust.

"So the bigger bore allowed us to go bigger with the valve and stand the valve angles up three degrees on both valves. That allows us to run a shallower chamber. Effectively we can get a lot better flowing cylinder head on both intake and exhaust than we could have with our normal 4.8 bore center. Now one of the other biggest factors was we spread the lifter spacing from 2" to 3.250". Not only does it make the valve train geometry absolutely perfect as far as push rod angles to rocker locations, it allows us to not have any push rod bulges in the intake port. It frees us up with a lot more intake port development than we could have done with the 2" lifter spread in our current 4.8 Hemi. The biggest factor is we have a lot better cylinder head than we could have with our 4.8.

"You can run up to a 5/8" diameter push rod if you want on both the intake and exhaust. There's also two different rocker assemblies available. Reid makes a dual shaft assembly similar to a normal 4.8 Hemi. We also do our own individual shaft system that T&D made for us and we made the stands. It gives our customers a couple different options. They can go with a conventional dual shaft system, or if they want to go with something a little newer and a little more lightweight, they can go with our system. The T&D assembly is close to 14 lbs lighter than a conventional assembly. You can change rocker ratios very easily, which really helps us out on the dyno in engine development. You can put less ratio on the exhaust or more on the intake pretty quickly. Instead of changing camshafts, you can do a lot with rocker ratios, then go back to the camshaft design protocol after that.

"Also, we raised the cam up 1.250" as well from our 4.8 Hemi. This allows us to run a lot bigger cam diameter. We can run a 70 mm roller bearing or a 75 mm babbit bearing cam. We can get a lot more aggressive with our camshaft profiles because we have a lot bigger base circle now than what we had with the normal 65 mm cam in the 4.8. There will be a lot more freedom in camshaft development. We can get a lot more aggressive, but keep the valvetrain under control.

"With the wider bore center, we are able to move the head studs away from the cylinder walls, it allows us to keep the bores a lot truer than we can with our current 4.8 head stud package. The 9/16" studs are really close to the cylinder wall in the 4.8. Moving the studs makes the bore a lot stronger by moving the head studs away from the cylinder wall.

"On the main caps, we use a 30 degree splayed caps. The side bolts are kicked up 30 degrees. What we found on the 4.8 Hemi, having the side bolt on a 90 degree, it really is not sharing any load from the pan rail. With us kicking the side bolt up 30 degrees, it actually spreads the torsional load across the whole cap, not point loading on top of the 9/16" fastener. It is a lot stronger main cap design. It is double registered to the block; one of the registers is at 30 degrees. It interlocks the cap to the block. This adds a lot of strength to the block since the cap and the block are interlocked.

"We also put a Big Block Chevy rear thrust bearing on it. So it has a lot wider thrust-rear cap. It's much wider than the standard Hemi center thrust. If you look at the Miner Bros. engine or the 481x engines that have the Chevy rear thrust, those two engines have zero rear main issues at all. That's why we chose to switch to that style rear thrust.

"Another similar feature is intake manifold is doweled onto the block, so you can pull the cylinder heads off, and leave the blower, manifold, blower belt and everything in tact. You can get a head off and get a piston out in five minutes pretty easily with two guys.

"It's pretty user friendly with the changes we made. We tried to make the best part we could and make it user friendly."

IPM: So this motor will be available for the NHRA legal rules as well?

JN: "Yes. It will also be available is a 2.400/1.900 head for NHRA. What we done with that cylinder head is stood the valve up even further, and ran a lot shallower chamber. The chamber is down to 76 cc from 98-99 cc. That allows you to run a lot less dome on the piston, to keep the piston weight down and keep the flame travel from having to go over a big dome."

IPM: Will you be offering a turbo version as well?

JN: "Yes. The turbo version will be offered in the NHRA legal small valve and the big valve outlaw stuff as well. The manifold is obviously different. We're actually making a couple of engines now for a couple of heavy hitters that are going to switch to this engine. We are building six complete motors for them at the shop now. We hope to see them on the track in the next four to eight weeks."

IPM: How much development work have you been able to do on the dyno?

JN: "At the moment it has only been dynoed with a screw blower. We are building the roots blower engine now. Obviously the compression ratio is a big factor between a screw blown outlaw motor to a roots blown NHRA motor. We had to change the internals as far as camshaft, compression ratio. The cylinder head is different and the intake manifold is completely different for a roots than our screw blower intake. The very first dyno pull that we made on it - we only had 22 degrees of timing in it to just get some data on it. It proved to be the very best engine that we have ever dynoed on our very first pull.

now. Obviously the compression ratio is a big factor between a screw blown outlaw motor to a roots blown NHRA motor. We had to change the internals as far as camshaft, compression ratio. The cylinder head is different and the intake manifold is completely different for a roots than our screw blower intake. The very first dyno pull that we made on it - we only had 22 degrees of timing in it to just get some data on it. It proved to be the very best engine that we have ever dynoed on our very first pull.

"That was a pretty big surprise. We thought because we changed so much stuff, we thought we might have been behind the game a little bit at first, then have to tweak it, work with it and change some stuff. Judging from the first dyno pull, it shows that everything that we did was moving in the right direction.

"We are no strangers to this. We have been involved in blown alcohol engines, manufacturing cylinder heads and now complete engines. So when we design a complete engine from scratch like this, we sort of know what works and doesn't work. It worked out pretty good."

IPM: So teams will be able to get everything to make the switch direct from you? Will teams be able to use their preferred manufacturers for internal components?

JN: "The turbo, screw blown and roots blown stuff will be available through us. We keep cranks and cams in stock since it's not an off the shelf item anymore. We can sell blank cam cores, so racers can get their own grind done. We can supply the chamber models to their piston manufacturers if they have a sponsorship deal or relationship with. You don't have to buy everything from us. As far as the internal stuff, we are happy to work with the racers to give their supplier the data they need to make the parts. It's not a monopoly that they have to buy everything through us."

IPM: Getting to the cost issue, what is the cost of one of these 4.9 motors compared to the traditional 4.8?

JN: "It's a lot more unique engine than what is available now. We tried to keep the engine as affordable as we can. It works out to be about $10,000 more than our current 4.8 manifold to pan combo. It's not a lot different. The main difference for the price is the cam core is a little more expensive, the crank is a little more expensive, there's a lot more machine time in this motor than our 4.8 stuff. That's really where most of the additional cost is coming from. We didn't want to price it out of the market where no one could afford it. We tried to keep the pricing reasonable, but the components in it are more expensive. Take for example, it takes a keyed lifter, so the lifters themselves are $600 more expensive than the traditional lifters in our 4.8. So the lifter bushes, the 70 mm roller bearings, it just all adds up. Still, the price is very competitive for this caliber of engine."

JN: "It's a lot more unique engine than what is available now. We tried to keep the engine as affordable as we can. It works out to be about $10,000 more than our current 4.8 manifold to pan combo. It's not a lot different. The main difference for the price is the cam core is a little more expensive, the crank is a little more expensive, there's a lot more machine time in this motor than our 4.8 stuff. That's really where most of the additional cost is coming from. We didn't want to price it out of the market where no one could afford it. We tried to keep the pricing reasonable, but the components in it are more expensive. Take for example, it takes a keyed lifter, so the lifters themselves are $600 more expensive than the traditional lifters in our 4.8. So the lifter bushes, the 70 mm roller bearings, it just all adds up. Still, the price is very competitive for this caliber of engine."

IPM: What are some of the changes a racer can expect to have to make outside of the engine to make the switch?

JN: The bellhousing and front engine mounts are identical to the Hemi. We had to eliminate the mag drive. When you spread the lifter out that much, there's no room for a cam gear to put the mag drive in the conventional spot. We drive the mag off the front between the fuel pump and oil pump. The oil pump is also driven off the front with a flange mount oil pump. The block is .250" longer than our 4.8. In addition to stretching the bore center, we have made the main bearings a lot wider. What we tried to do was stack all the gear drive back in to not make it any longer than the conventional 4.8 block, but it just wasn't possible to get that done.

"The best of the best is in this motor. All tool steel 5/8" head studs, all tool steel 5/8" main studs, all tool steel side bolts. It's not something people would buy and go put a cheap set of studs or lifters in it. I wouldn't sell it without the best of the best on it. That's not what we are about. We are about providing the best engine that we can with all the best components you can buy. With all that said, it's only $10,000 more than conventional 4.8 bore space hemi."

side bolts. It's not something people would buy and go put a cheap set of studs or lifters in it. I wouldn't sell it without the best of the best on it. That's not what we are about. We are about providing the best engine that we can with all the best components you can buy. With all that said, it's only $10,000 more than conventional 4.8 bore space hemi."

IPM: What kind of assistance do you offer a new customer getting up to speed with the new motor?

JN: "We for sure will help any of our customers. We have learned a fair bit over the years of racing ourselves. We also have very good info from the dyno. What we have found on the dyno corresponds to the track. We could put a tune up on the dyno, come up with a correction factor, go to the track. With just some small little changes the engine is going to be 100% right on the first pass. We are happy to assist anyone that switches to our new engine.

"New for this year is we have added veteran Top Alcohol Funny Car and Pro Mod racer Clint Thompson to our team as National Sales Manager for the US. We look forward to having Clint on board full time to work with our new and existing customers."

IPM: Thanks for your time. It was a lot of great information and we have a lot of typing to do!

About Noonan Racing

Noonan Ultimate Race Engineering is one of Australia’s premier race engine building and development facilities and a world leader in billet component innovation. In addition to its headquarters at Yatala (Queensland, Australia), the company has opened a U.S. location in Lindon, Utah, to keep up with development and service of its world-renowned line of products. Their track-proven products were utilized in 2016 during the NHRA Top Alcohol championship-winning efforts of Joey Severance and Jonnie Lindberg, and by nine-time Australian Top Doorslammer Legend – John Zappia.

Offering engine components for motor racing including drag racing, tractor pull, drag boat racing, and the diehard enthusiast wanting the competitive edge over their opponents, Noonan Ultimate Race Engineering is committed to putting racers first. For more information, visit www.noonanrace.com {{http://www.noonanrace.com/}} . You can also follow on social media platforms such as Facebook (Noonan Race Engineering) and Instagram (@noonanraceengineering). You can contact Clint Thompson direct at (541) 944-4141 or [email protected]

InsideProMod (IPM): Tell us the basics of this new motor. What are the major differences in the 4.9 Hemi and the 4.8 Hemi (Fathead style that most run), and why did you go in that direction?

Jamie Noonan (JN): "Obviously the bore center was a big factor. We went from 4.8 to 4.9 bore centers. So we can actually take up to 4.600 bore now where we were limited to 4.500 bore before. Which allows us for the PDRA Pro Mod cars to run a much bigger intake and exhaust valve than we could with the 4.500 bore. Not only did we go bigger with the valves, we stood the valve angles up three degrees so it flattens the chamber out, and raised the port up half an inch on intake and exhaust.

Jamie Noonan (JN): "Obviously the bore center was a big factor. We went from 4.8 to 4.9 bore centers. So we can actually take up to 4.600 bore now where we were limited to 4.500 bore before. Which allows us for the PDRA Pro Mod cars to run a much bigger intake and exhaust valve than we could with the 4.500 bore. Not only did we go bigger with the valves, we stood the valve angles up three degrees so it flattens the chamber out, and raised the port up half an inch on intake and exhaust."So the bigger bore allowed us to go bigger with the valve and stand the valve angles up three degrees on both valves. That allows us to run a shallower chamber. Effectively we can get a lot better flowing cylinder head on both intake and exhaust than we could have with our normal 4.8 bore center. Now one of the other biggest factors was we spread the lifter spacing from 2" to 3.250". Not only does it make the valve train geometry absolutely perfect as far as push rod angles to rocker locations, it allows us to not have any push rod bulges in the intake port. It frees us up with a lot more intake port development than we could have done with the 2" lifter spread in our current 4.8 Hemi. The biggest factor is we have a lot better cylinder head than we could have with our 4.8.

"You can run up to a 5/8" diameter push rod if you want on both the intake and exhaust. There's also two different rocker assemblies available. Reid makes a dual shaft assembly similar to a normal 4.8 Hemi. We also do our own individual shaft system that T&D made for us and we made the stands. It gives our customers a couple different options. They can go with a conventional dual shaft system, or if they want to go with something a little newer and a little more lightweight, they can go with our system. The T&D assembly is close to 14 lbs lighter than a conventional assembly. You can change rocker ratios very easily, which really helps us out on the dyno in engine development. You can put less ratio on the exhaust or more on the intake pretty quickly. Instead of changing camshafts, you can do a lot with rocker ratios, then go back to the camshaft design protocol after that.

"Also, we raised the cam up 1.250" as well from our 4.8 Hemi. This allows us to run a lot bigger cam diameter. We can run a 70 mm roller bearing or a 75 mm babbit bearing cam. We can get a lot more aggressive with our camshaft profiles because we have a lot bigger base circle now than what we had with the normal 65 mm cam in the 4.8. There will be a lot more freedom in camshaft development. We can get a lot more aggressive, but keep the valvetrain under control.

"With the wider bore center, we are able to move the head studs away from the cylinder walls, it allows us to keep the bores a lot truer than we can with our current 4.8 head stud package. The 9/16" studs are really close to the cylinder wall in the 4.8. Moving the studs makes the bore a lot stronger by moving the head studs away from the cylinder wall.

"On the main caps, we use a 30 degree splayed caps. The side bolts are kicked up 30 degrees. What we found on the 4.8 Hemi, having the side bolt on a 90 degree, it really is not sharing any load from the pan rail. With us kicking the side bolt up 30 degrees, it actually spreads the torsional load across the whole cap, not point loading on top of the 9/16" fastener. It is a lot stronger main cap design. It is double registered to the block; one of the registers is at 30 degrees. It interlocks the cap to the block. This adds a lot of strength to the block since the cap and the block are interlocked.

"We also put a Big Block Chevy rear thrust bearing on it. So it has a lot wider thrust-rear cap. It's much wider than the standard Hemi center thrust. If you look at the Miner Bros. engine or the 481x engines that have the Chevy rear thrust, those two engines have zero rear main issues at all. That's why we chose to switch to that style rear thrust.

"Another similar feature is intake manifold is doweled onto the block, so you can pull the cylinder heads off, and leave the blower, manifold, blower belt and everything in tact. You can get a head off and get a piston out in five minutes pretty easily with two guys.

"It's pretty user friendly with the changes we made. We tried to make the best part we could and make it user friendly."

IPM: So this motor will be available for the NHRA legal rules as well?

JN: "Yes. It will also be available is a 2.400/1.900 head for NHRA. What we done with that cylinder head is stood the valve up even further, and ran a lot shallower chamber. The chamber is down to 76 cc from 98-99 cc. That allows you to run a lot less dome on the piston, to keep the piston weight down and keep the flame travel from having to go over a big dome."

IPM: Will you be offering a turbo version as well?

JN: "Yes. The turbo version will be offered in the NHRA legal small valve and the big valve outlaw stuff as well. The manifold is obviously different. We're actually making a couple of engines now for a couple of heavy hitters that are going to switch to this engine. We are building six complete motors for them at the shop now. We hope to see them on the track in the next four to eight weeks."

IPM: How much development work have you been able to do on the dyno?

JN: "At the moment it has only been dynoed with a screw blower. We are building the roots blower engine

now. Obviously the compression ratio is a big factor between a screw blown outlaw motor to a roots blown NHRA motor. We had to change the internals as far as camshaft, compression ratio. The cylinder head is different and the intake manifold is completely different for a roots than our screw blower intake. The very first dyno pull that we made on it - we only had 22 degrees of timing in it to just get some data on it. It proved to be the very best engine that we have ever dynoed on our very first pull.

now. Obviously the compression ratio is a big factor between a screw blown outlaw motor to a roots blown NHRA motor. We had to change the internals as far as camshaft, compression ratio. The cylinder head is different and the intake manifold is completely different for a roots than our screw blower intake. The very first dyno pull that we made on it - we only had 22 degrees of timing in it to just get some data on it. It proved to be the very best engine that we have ever dynoed on our very first pull."That was a pretty big surprise. We thought because we changed so much stuff, we thought we might have been behind the game a little bit at first, then have to tweak it, work with it and change some stuff. Judging from the first dyno pull, it shows that everything that we did was moving in the right direction.

"We are no strangers to this. We have been involved in blown alcohol engines, manufacturing cylinder heads and now complete engines. So when we design a complete engine from scratch like this, we sort of know what works and doesn't work. It worked out pretty good."

IPM: So teams will be able to get everything to make the switch direct from you? Will teams be able to use their preferred manufacturers for internal components?

JN: "The turbo, screw blown and roots blown stuff will be available through us. We keep cranks and cams in stock since it's not an off the shelf item anymore. We can sell blank cam cores, so racers can get their own grind done. We can supply the chamber models to their piston manufacturers if they have a sponsorship deal or relationship with. You don't have to buy everything from us. As far as the internal stuff, we are happy to work with the racers to give their supplier the data they need to make the parts. It's not a monopoly that they have to buy everything through us."

IPM: Getting to the cost issue, what is the cost of one of these 4.9 motors compared to the traditional 4.8?

JN: "It's a lot more unique engine than what is available now. We tried to keep the engine as affordable as we can. It works out to be about $10,000 more than our current 4.8 manifold to pan combo. It's not a lot different. The main difference for the price is the cam core is a little more expensive, the crank is a little more expensive, there's a lot more machine time in this motor than our 4.8 stuff. That's really where most of the additional cost is coming from. We didn't want to price it out of the market where no one could afford it. We tried to keep the pricing reasonable, but the components in it are more expensive. Take for example, it takes a keyed lifter, so the lifters themselves are $600 more expensive than the traditional lifters in our 4.8. So the lifter bushes, the 70 mm roller bearings, it just all adds up. Still, the price is very competitive for this caliber of engine."

JN: "It's a lot more unique engine than what is available now. We tried to keep the engine as affordable as we can. It works out to be about $10,000 more than our current 4.8 manifold to pan combo. It's not a lot different. The main difference for the price is the cam core is a little more expensive, the crank is a little more expensive, there's a lot more machine time in this motor than our 4.8 stuff. That's really where most of the additional cost is coming from. We didn't want to price it out of the market where no one could afford it. We tried to keep the pricing reasonable, but the components in it are more expensive. Take for example, it takes a keyed lifter, so the lifters themselves are $600 more expensive than the traditional lifters in our 4.8. So the lifter bushes, the 70 mm roller bearings, it just all adds up. Still, the price is very competitive for this caliber of engine."IPM: What are some of the changes a racer can expect to have to make outside of the engine to make the switch?

JN: The bellhousing and front engine mounts are identical to the Hemi. We had to eliminate the mag drive. When you spread the lifter out that much, there's no room for a cam gear to put the mag drive in the conventional spot. We drive the mag off the front between the fuel pump and oil pump. The oil pump is also driven off the front with a flange mount oil pump. The block is .250" longer than our 4.8. In addition to stretching the bore center, we have made the main bearings a lot wider. What we tried to do was stack all the gear drive back in to not make it any longer than the conventional 4.8 block, but it just wasn't possible to get that done.

"The best of the best is in this motor. All tool steel 5/8" head studs, all tool steel 5/8" main studs, all tool steel

side bolts. It's not something people would buy and go put a cheap set of studs or lifters in it. I wouldn't sell it without the best of the best on it. That's not what we are about. We are about providing the best engine that we can with all the best components you can buy. With all that said, it's only $10,000 more than conventional 4.8 bore space hemi."

side bolts. It's not something people would buy and go put a cheap set of studs or lifters in it. I wouldn't sell it without the best of the best on it. That's not what we are about. We are about providing the best engine that we can with all the best components you can buy. With all that said, it's only $10,000 more than conventional 4.8 bore space hemi."IPM: What kind of assistance do you offer a new customer getting up to speed with the new motor?

JN: "We for sure will help any of our customers. We have learned a fair bit over the years of racing ourselves. We also have very good info from the dyno. What we have found on the dyno corresponds to the track. We could put a tune up on the dyno, come up with a correction factor, go to the track. With just some small little changes the engine is going to be 100% right on the first pass. We are happy to assist anyone that switches to our new engine.

"New for this year is we have added veteran Top Alcohol Funny Car and Pro Mod racer Clint Thompson to our team as National Sales Manager for the US. We look forward to having Clint on board full time to work with our new and existing customers."

IPM: Thanks for your time. It was a lot of great information and we have a lot of typing to do!

About Noonan Racing

Noonan Ultimate Race Engineering is one of Australia’s premier race engine building and development facilities and a world leader in billet component innovation. In addition to its headquarters at Yatala (Queensland, Australia), the company has opened a U.S. location in Lindon, Utah, to keep up with development and service of its world-renowned line of products. Their track-proven products were utilized in 2016 during the NHRA Top Alcohol championship-winning efforts of Joey Severance and Jonnie Lindberg, and by nine-time Australian Top Doorslammer Legend – John Zappia.

Offering engine components for motor racing including drag racing, tractor pull, drag boat racing, and the diehard enthusiast wanting the competitive edge over their opponents, Noonan Ultimate Race Engineering is committed to putting racers first. For more information, visit www.noonanrace.com {{http://www.noonanrace.com/}} . You can also follow on social media platforms such as Facebook (Noonan Race Engineering) and Instagram (@noonanraceengineering). You can contact Clint Thompson direct at (541) 944-4141 or [email protected]

Last edited: